Facility Management Case Study

Summary:

Our client, one of the leading facility management teams responsible for overseeing daily building operations such as maintenance, repairs, inspections, and cleaning, faced significant challenges due to reliance on Excel spreadsheets, which caused delays, missed updates, and a lack of real-time visibility into operations. Vendor coordination with electricians, plumbers, and contractors was fragmented, and reporting was slow and manual.

To address these issues, QPunch was implemented to centralise facility operations. By introducing live work order tracking, preventive scheduling, vendor coordination, advanced reporting, and resource utilization, QPunch replaced spreadsheets with a dynamic interactive system. This streamlined their daily operations, improved accountability, and provided management with transparent dashboards for real-time decision-making.

“QPunch is very user-friendly and helps update work in real-time, as once a query is raised, everyone involved can immediately see it and take action. This has helped us complete work much faster and keep operations on track.” – SEC Manager

Challenges:

The client faced the following key challenges in their daily facility work orders:

1. Excel Dependency: The work orders, like cleaning, patching, testing, plumbing repairs, and others, were tracked in outdated spreadsheets, which caused missed updates, duplication, and poor accountability.

2. Lack of Real-Time Updates: Teams had no live visibility of work order status, whether they were completed, pending, or overdue.

3. Poor Vendor Coordination: External vendors such as electricians, plumbers, and cleaning staff were managed separately via calls/emails, with no single source of communication.

4. Inefficient Reporting: Weekly performance reports required manual compilation from Excel, delaying compliance and oversight.

5. Resource Mismanagement: Managers had no visibility into staff workloads, planned vs. actual hours, or utilization trends, which led to inefficiencies and uneven workload distribution.

Requirements:

To address these challenges, the client outlined the following key requirements:

1. Centralised Tracking: Replace Excel with a single system for work order progress tracking.

2. Preventive Scheduling: Enable recurring and scheduled maintenance work orders.

3. Workload Analysis: Track planned vs. actual hours for better resource visibility.

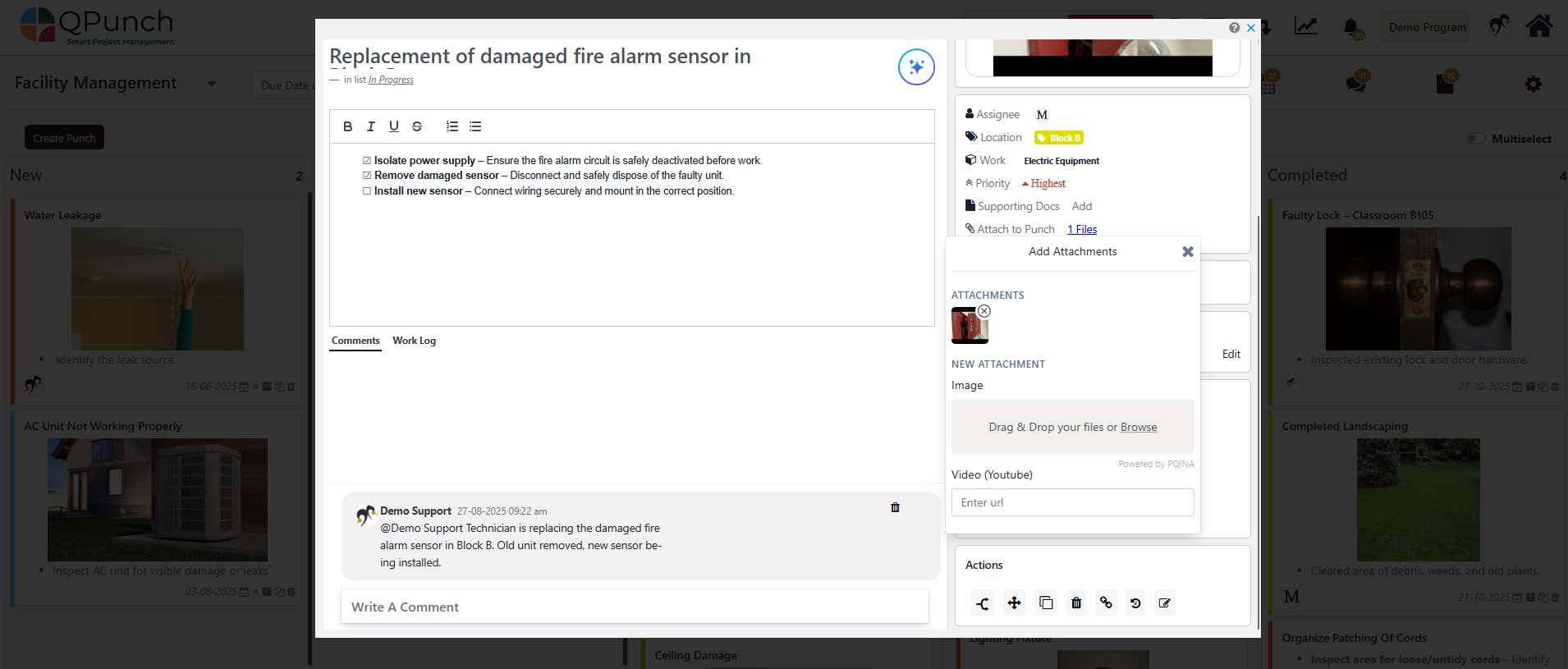

4. Vendor Updates: Allow vendors to add status, photos, and attachments directly in the system.

4. Visual Planning: Provide Kanban and Gantt chart views for daily operations and dependencies.

5. Instant Reporting: Generate real-time dashboards for compliance, workload, and management oversight.

Solution:

To overcome these issues like Excel dependency, lack of real-time updates, fragmented vendor coordination, and manual reporting, QPunch was implemented. Workflows were established through Kanban boards and Gantt charts, while advanced reporting and utilization tracking replaced manual processes. Staff and vendors were onboarded with simple training for smooth adoption.

Implementation Approach:

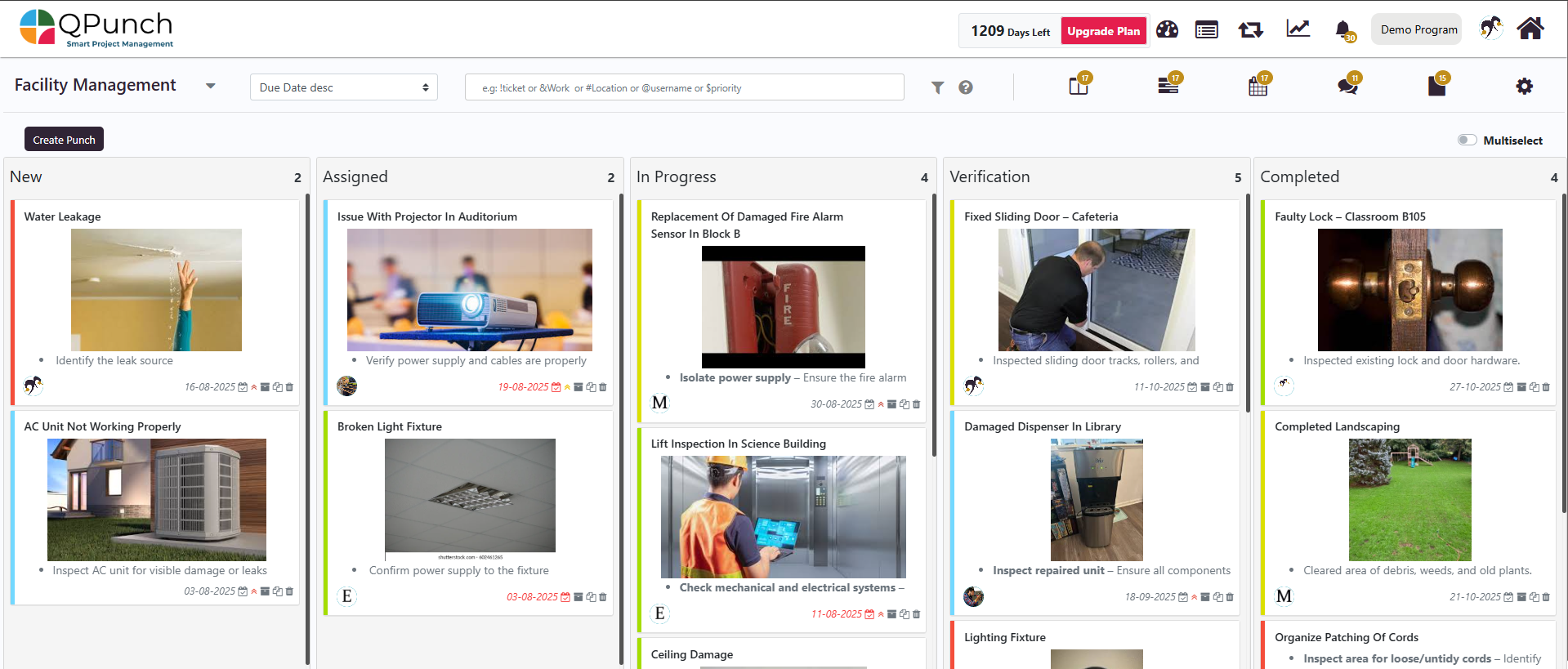

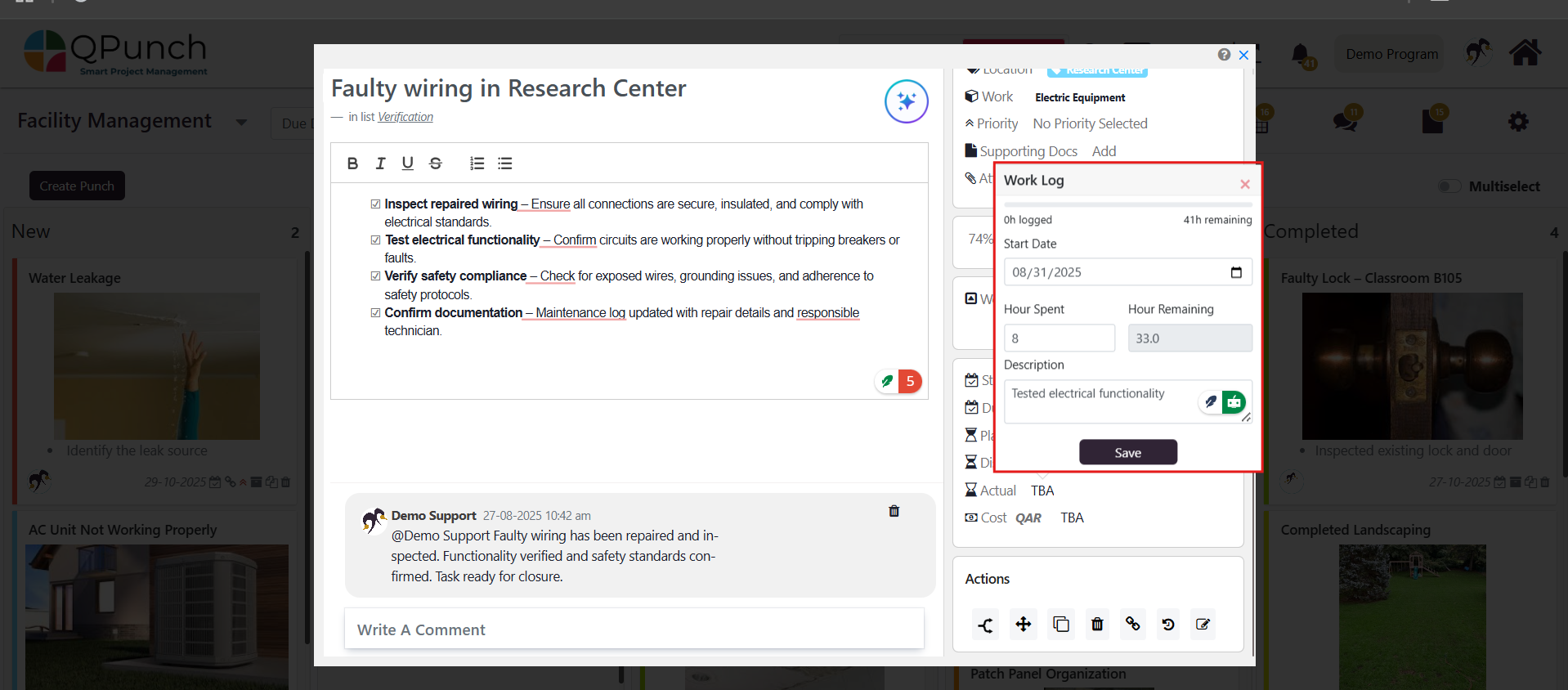

Solution for Work Order & Vendor Update Management: Centralised Kanban Boards.

QPunch seamlessly centralised their work orders through Kanban boards, where all facility operations, such as repairs, inspections, landscaping, and cleaning, were managed

With the help of QPunch, vendors like electricians and plumbers were directly assigned work orders where they could provide updates, upload photos, and attach reports. This eliminated fragmented communication and the need for constant calls and emails while improving accountability

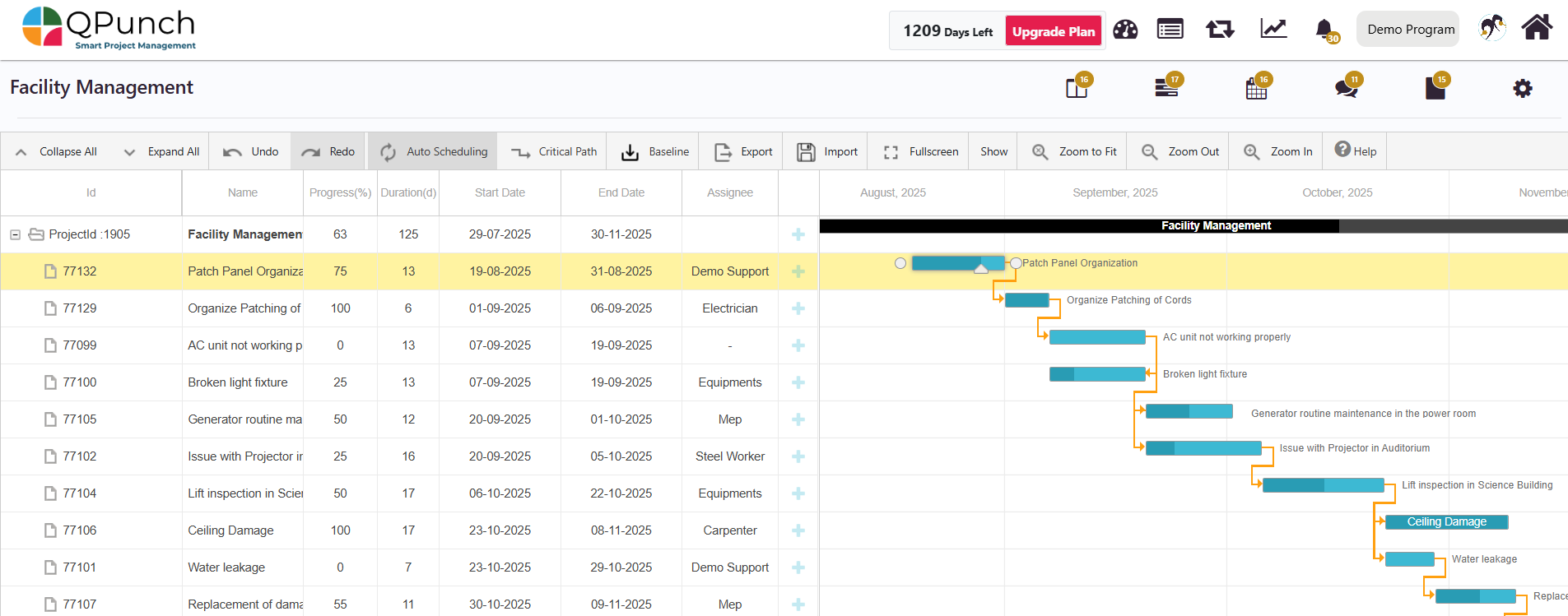

Solution for Preventive Scheduling – Gantt Chart Planning.

QPunch helped the team to schedule recurring operations such as monthly inspections, annual cleanings, and landscaping directly in Gantt charts by linking work order dependencies. This ensured sequential execution and proactive planning. Structured scheduling allowed resources to be allocated efficiently, minimized delays, and improved the overall effectiveness of preventive maintenance.

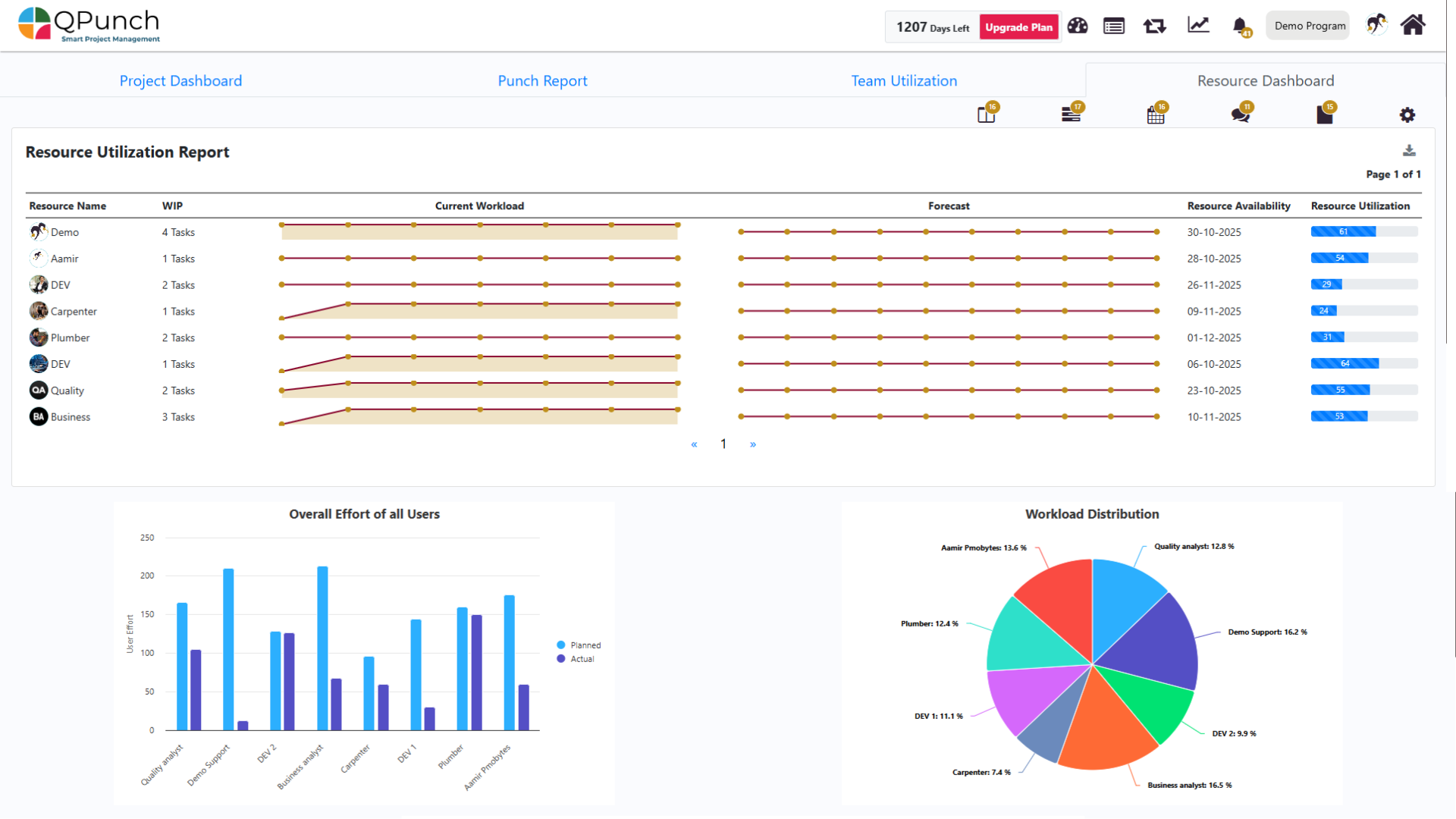

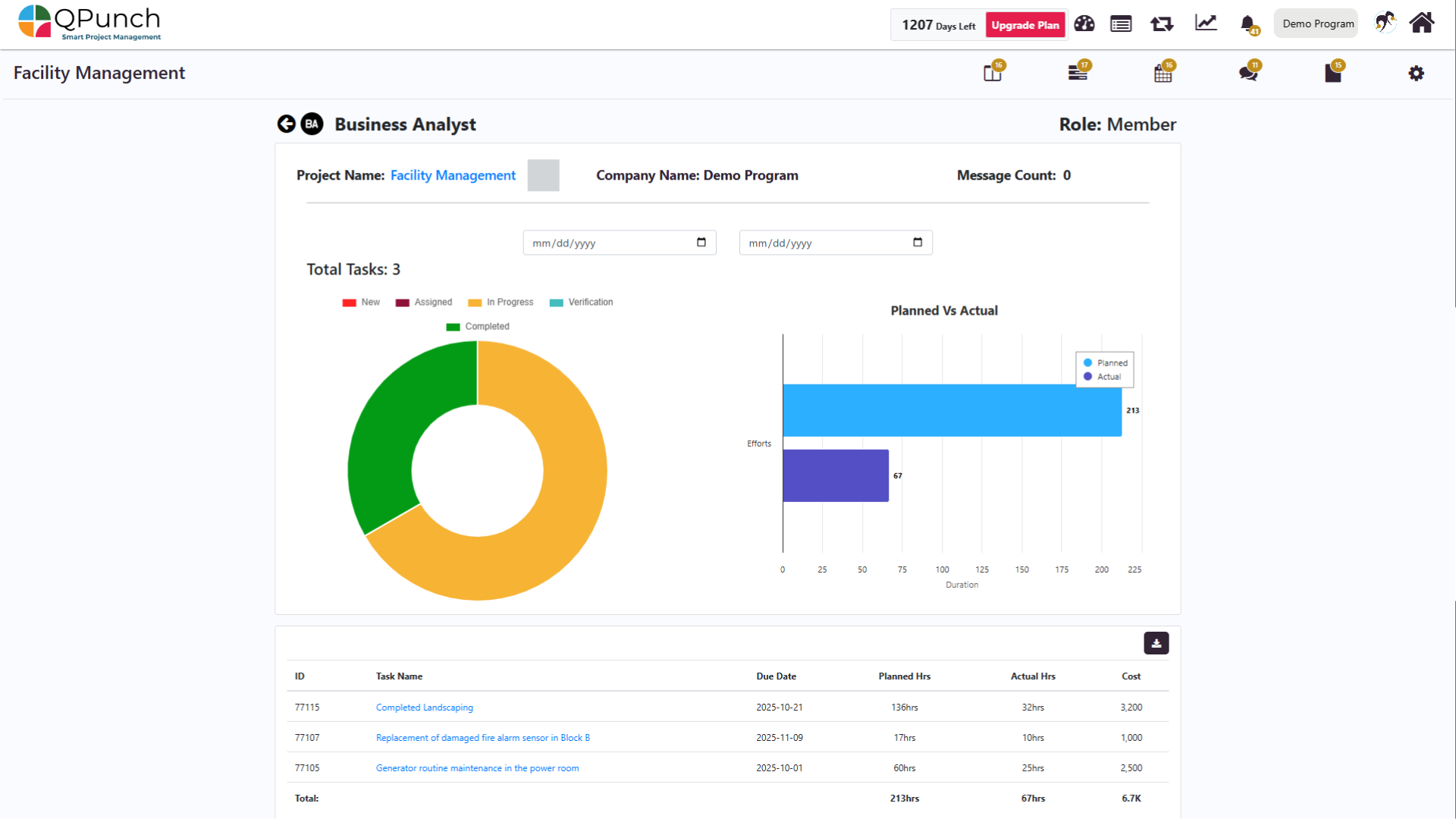

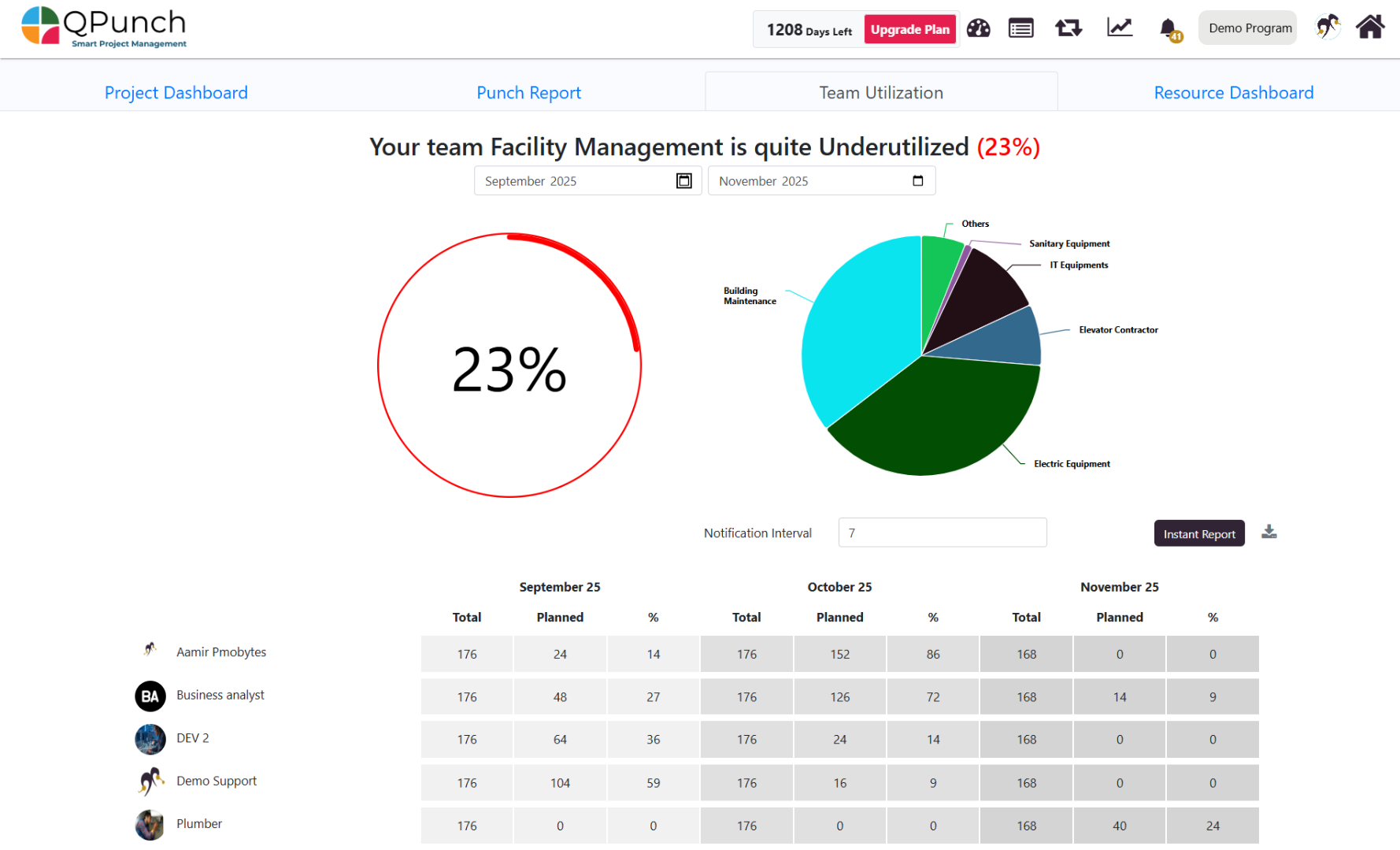

Solution for Resource Utilization – Worklogs and Utilization Report.

QPunch helped the facility staff log their actual working hours against planned hours, providing clear visibility into workload and resource utilization.

The tool helped the manager track work order status, compare planned versus actual hours, and monitor overall progress for resources. This made it easier to quickly identify over- or under-utilization, optimise staff assignments, and improve capacity planning for better efficiency.

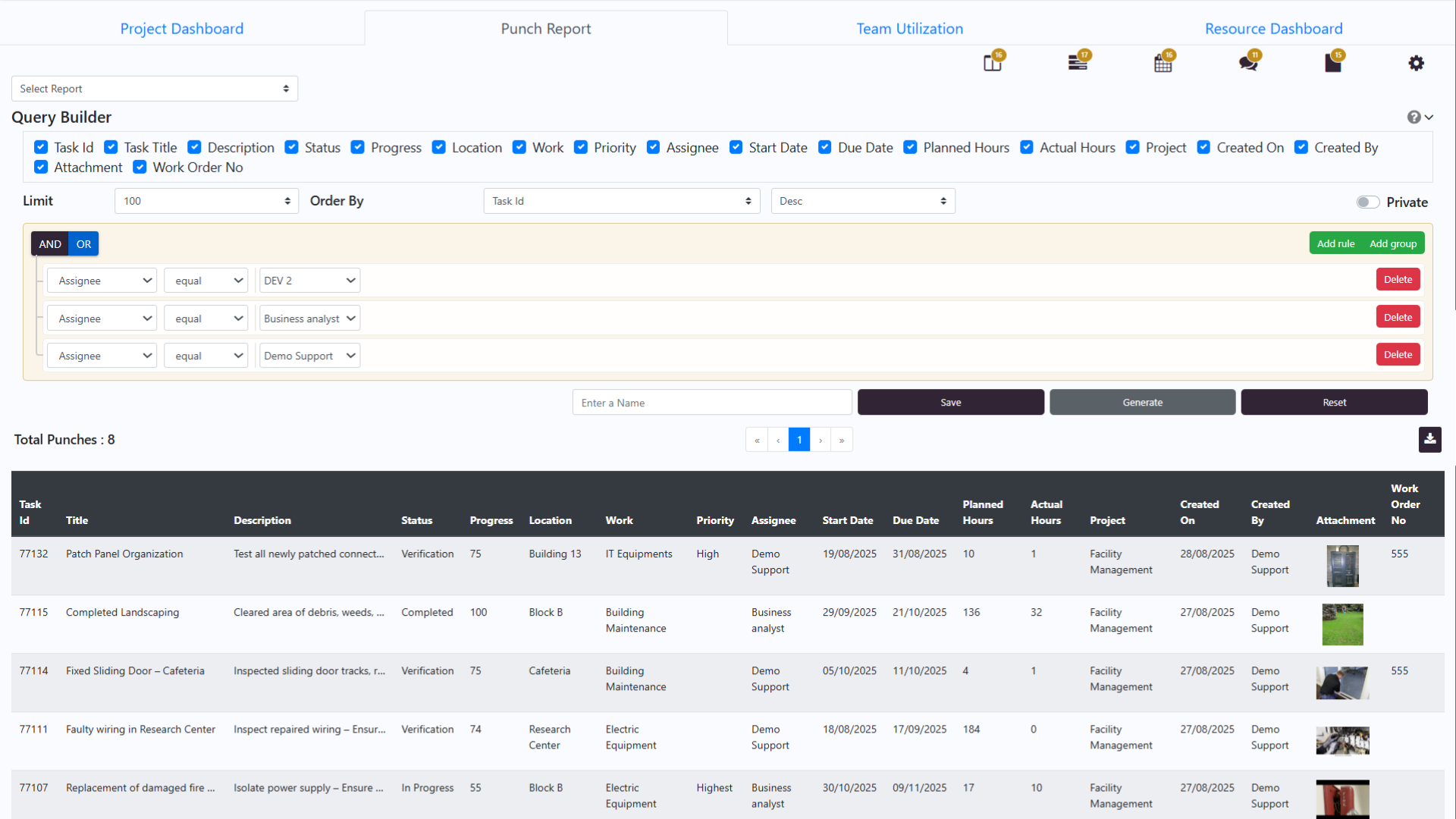

Solution for Advanced Reporting – Dynamic Report.

QPunch helped the facility team get real-time insights into projects and user data with flexible work order filtering and analysis. They could filter work orders by assignee, label, duration, and more, create and save reports, export them to Excel, and refresh instantly to see the latest updates. This turned reporting from a static, manual process into an interactive tool, making compliance, audits, and decision-making faster and easier.

Solution for Team Utilization – Workload Distribution.

QPunch also gave managers a team-wide utilization view through workload distribution reports. These reports showed who was working on which work orders, when they were scheduled, and how workloads were spread across the team. This visibility helped managers balance resources, avoid bottlenecks, and ensure performance stayed on track.

Benefits & Results:

By deploying QPunch, the facility management team achieved significant improvements in daily operations, including:

1. Replaced Excel: Moved from static spreadsheets to a live, centralised platform.

2. 50% Faster Reporting: Dynamic reports and dashboards eliminated manual reporting delays.

3. Improved Vendor Accountability: Contractors updated work orders directly in QPunch with photos and attachments.

4. 40% More Efficient Preventive Maintenance: Gantt scheduling reduced delays and improved planning.

5. Accurate Resource Utilization: Worklogs and dashboards optimized staff workloads.

6. Smarter Decisions: Real-time data gave managers the confidence to act faster and more effectively.

“In QPunch, whenever we log a query with photos and details, everyone involved is instantly notified to take action and close it once it is resolved. Compared to other systems, QPunch is simple, efficient, and gives us exactly what we need to manage our operations smoothly.” – Mechanical QC

Conclusion:

By deploying QPunch, the facility management team achieved significant improvements in daily operations, including faster reporting, smoother vendor coordination, efficient preventive maintenance, and accurate resource utilization. QPunch successfully transformed its approach to facility operations by replacing static Excel spreadsheets with a centralised, real-time system. The result was enhanced transparency, improved accountability, and measurable operational efficiency.

Address On Maps

Ready To Get Started with Smart Project Management?